Outdoor Direct Burial Fiber Optic Armoured Cable GYTA53 GYTS53 Direct Buried Single Mode

Product Details:

| Place of Origin: | SHENZHEN |

| Brand Name: | KEXINT |

| Certification: | ISO-9001 |

| Model Number: | GYTA53 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiation |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 1.1*0.72*1.1m 2km~4km ,Length per roll , Wooden Drum |

| Delivery Time: | 8 |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 90+KM+24H |

|

Detail Information |

|||

| Model Number: | GYTS53/GYTA53 | Strength Member: | Steel Wire/FRP Strength Member |

|---|---|---|---|

| Product Name: | Outdoor Fiber Optical Cable | Fiber Type: | G657A1/G657A2 |

| Armour: | Steel /Aluminium Tape | Application: | Outdoor Aerial Application |

| Sheath Color: | Black | Package: | Wooden Drum |

| Highlight: | armored network cable,armoured fiber cable |

||

Product Description

Outdoor Direct Burial Fiber Optic Armoured Cable GYTA53 GYTS53 Direct Buried Single Mode

Outdoor Fiber Optic Armoured Cable

GYTA53-24B1.3

Product Description:

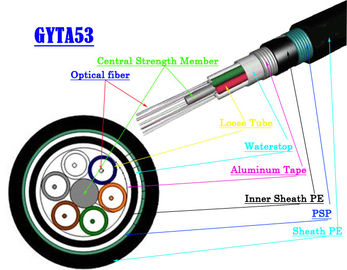

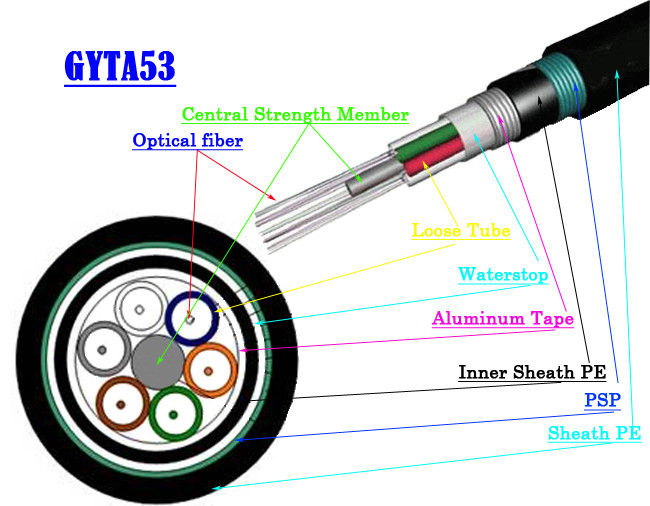

GYTA53 uses metal strength member as central strength member to provide excellent strain performance of the cable. Double-jacket structure provide the cable nice properties of moisture resistance and crush resistance. Double armor structure provides cable good property of rodent-resistance. High strength loose tube is hydrolysis resistant. A layer of water-blocking material is applied around the cable core to prevent water ingress. It can be used for duct and direct buried application, suitable for harsh environments.

Feature:

1. Good mechanical and temperature performance

2. High strength loose tube that is hydrolysis resistant

3. Special tube filling compound ensures a critical protection of fiber

4. Crush resistance and flexibility

5. The following measures are taken to ensure the cable watertight:

a. Steel wire used as the central strength member

b. Loose tube filling compound

c. 100% cable core filling

d. APL moisture barrier

e. Water-blocking material

Cable design:

- 24 SM-fibers.

- 6 SM-fibers placed in each tube.

- Steel wire as central strength member.

- Loose buffer tubes SZ-stranded.

- The buffered tube filled with filling compound while the stranded core covered with water block material.

- Aluminum tape as the moisture barrier.

- PE Cable inner sheath.

- Corrugated stainless steel tape armored.

- HDPE Cable Outer sheath.

- Suitable as: Direct-buried installation.

1 Reference Standard

IEC 60793-1, 60793-2, 60794-1

ITU-T G650, G652

2 Optical and mechanical characteristics of fiber

| MFD(1310nm) | 9.2mm±0.4mm |

| MFD(1550nm) | 10.4mm±0.8mm |

| Cladding diameter | 125mm±1.0mm |

| Fiber diameter | 250 ± 15 mm (Colored) |

| Core/cladding concentricity error | £0.6mm |

| Cladding non circularity | £1.0% |

| Cut off wavelength | £1260nm |

| Attenuation coefficient | 1310nm: £0.36dB/km |

| 1550nm: £0.22dB/km | |

| Bending-loss performance of optical fiber | £0.05dB |

| Polarization mode dispersion | £0.1ps/Ökm |

| Zero-dispersion wavelength | 1300 – 1324 nm |

| Zero-dispersion slope | £0.092ps/(nm2•km) |

3 Mechanical requirements and methods of fiber cable

| Tensile strength | 3000N, conform to IEC 794-1-E1 while fiber strain ≤0.33% |

| Crush | 3000N/100mm, conform to IEC 794-1-E3 |

| Impact | Conform to IEC 794-1-E4 |

| Repeated bending | Conform to IEC 794-1-E6 |

| Torsion | Conform to IEC 794-1-E7 |

| Flexing | Conform to IEC 794-1-E8 |

| Kink | Conform to IEC 794-1-E10 |

| Cable bend | Conform to IEC 794-1-E11 |

| Water penetration | Conform to IEC 794-1-F5B |

| The dielectric strength of outer jacket | Conform to ITU-T Rec.K25 |

| Spark test voltage | Spark test voltage of cable outer jacket will be no less than 8kV AC |

| Abrasion | Conform to IEC 794-1-E2 |

| Temperature cycling test | Conform to IEC 794-1-F1 |

4 Fiber color coding and tube color coding

![]()

5 Structure

![]()

6 Mechanical specification

| Items | Descriptions | ||

| Optical fiber | Category | G.652D | |

| Counts | 24 | ||

|

Number of fibers per tube |

Counts | 6 | |

| Central strength member | Material | Steel wire | |

| Diameter (mm) | 1.55 | ||

| Loose tube | Material | PBT | |

| Diameter (mm) | 2.0 | ||

| Counts | 4 | ||

| Filler rod | Counts | 1 | |

| Moisture proof | Material | Corrugated Al tape | |

| Inner sheath | Material | PE | |

| Thickness (mm) | Nominal 0.8 | ||

| Armor | Material | Corrugated stainless steel tape | |

| Outer sheath | Material | HDPE | |

| Thickness (mm) | Nominal 1.7 | ||

| Cable diameter (mm)±0.5 | 12.5 | ||

| Cable weight (kg/km)±10% | 160 | ||

| Tensile strength | Short term (N) | 3000 | |

| Long term (N) | 1000 | ||

| Crush | Short term (N/10cm) | 3000 | |

| Long term (N/10cm) | 1000 | ||

| Applicable temperature range | Operation | - 45℃ ~ +70℃ | |

| Installation | - 20℃ ~ +60℃ | ||

| Storage & shipping | - 45℃ ~ +70℃ | ||

| Bending Radius | Unloaded | 12.5 times of outer diameter | |

| Loaded | 25 times of outer diameter | ||

7 Environmentally

The product is accord with the instruction of ISO 14001and EU ROHS (Pb-Free in ZTE)

8 Packing and Logo

8.1 Packing

8.1.1 Each single length of cable shall be wound on an Iron stand-wooden composite drum.

8.1.2 Covered by plastic buffer sheet.

8.1.3 Sealed by strong wooden battens.

8.1.4 Drum length

8.1.4.1 Standard drum length is 3000m;

8.1.4.2 Total quantity is at least the ordered quantity.

8.1.4.3 Or it can be delivered according to customers’ requirements, but not longer than 5000m.

8.2. Drum Marking

- Manufacturer name;

- Manufacturing year and month;

- Roll-direction arrow;

- Cable outer end position indicating arrow;

- Cable type and size;

- Drum number;

- Drum length;

- Gross / net weight;

- Caution plate indicating the correct method for loading, unloading and convey the cable;

- Other customer information such as contract no., project no., and delivery destination. (if needed)

8.3 Cable identification documents

- Product qualified certificate;

- Test report.

- Accurate volume and weight information.

9 Environmentally

The product is accord with the instruction of EU ROHS