12 Core LSZH Fiber Cable , Fibre Optique G657A2 Air Blown Mini Dual Purpose

Product Details:

| Place of Origin: | SHENZHEN |

| Brand Name: | KEXINT |

| Certification: | ISO-9001 |

| Model Number: | GYFXTH |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiation |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 43*43*38cm 1km or 2km |

| Delivery Time: | 7 |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 60000+M+24H |

|

Detail Information |

|||

| Fiber Type: | G652D G657A1 G657A2 | Fiber Brand: | Corning/YOFC/FIBERHOME |

|---|---|---|---|

| Length Per Roll: | 1km To 4km | Application: | Outdoor Aerial Application |

| Sheath Color: | Blue Or Black | Type Of Optical Cable: | Power Optical Cable |

| Fiber Count: | 1~24 Core | Package: | Wooden Drum |

| Highlight: | armored fiber cable,armoured fiber cable |

||

Product Description

12 Core LSZH Fiber Cable , Fibre Optique G657A2 Air Blown Mini Dual Purpose

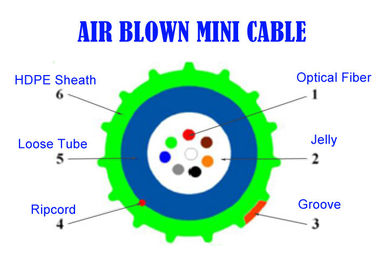

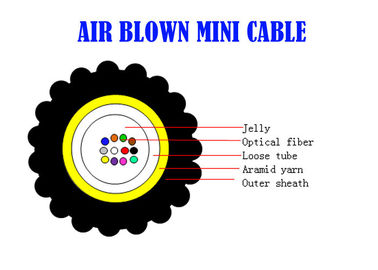

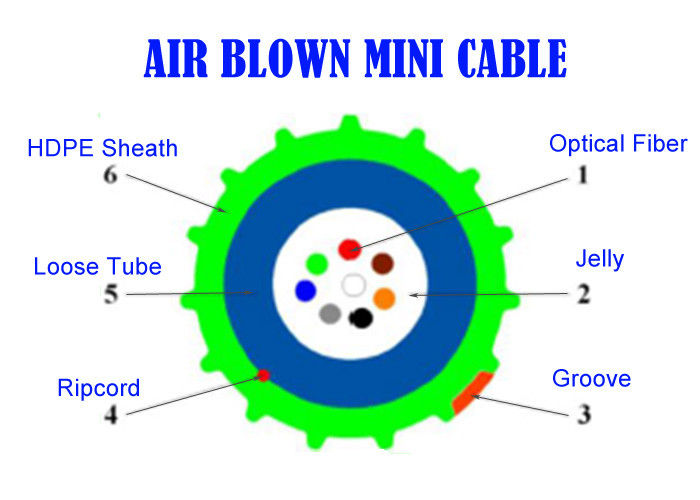

AIR BLOWN MINI CABLE

[ GCYFXTY]

Features and Benefits:

a. Special complex material loose tube, reduce the shrink of tube in cold temperature.

b. Accurate fiber length balance, stable mechanical and temperature performance.

c. Particular technique control, prevent sheath form crinkling during installation.

d. Structure Innovation in sheath, enhancing the blowing performance.

Technical Index:

| Cable Type | GCYFXTY-XB1.3(MTE + Cable diameter) | |||

| MTE2.0 | MTE2.3 | MTE2.5 | MTE2.8 | |

| Fiber Count | 2~4 | 6~12 | 2~12 | 14~24 |

| Thickness of HDPE sheath | Nominal value:0.20mm, Average value:0.15mm | |||

| Nominal Overall Diameter | 2.0±0.1mm | 2.3±0.1mm | 2.5±0.1mm | 2.8±0.1mm |

| Weight | 4.0 kg/km | 5.0 kg/km | 6.0 kg/km | 7.0kg/km |

| Cable Fiber Attenuation (single mode) | 0.35dB/km max @1310nm 0.22dB/km max @1550nm | |||

| Max. Tensile Strength | 40N | 50N | 60N | 60N |

| Max. Crushing force | 600N/100mm | |||

| Min. Bending radius -Static / Dynamic | 10 / 20 outer Φ | |||

| Temperature | Storage -30~+50℃;Installation-10~+40℃;Operation-20~+50℃ | |||

| Cable service life (estimate value) | 25 years | |||

Testing Index

Blowing performance

| Blowing Tool | Typical blowing length | ||

|

PLUMETTAZ:PR-140, MiniJet-400 etc. Air pressure : 13bar |

Fibers Count |

Duct type 3.5/5.0mm |

Duct type 5.5/7.0mm |

| 2~12 fibers | 800m | 1500m | |

| 14~24 fibers | 500m | 1500m | |

Mechanic performance

| Item | Testing Method | Testing Results | Specified Value | |

|

Tension performance |

IEC 60794-1-2-E1 | Optical fiber strain | Additional attenuation |

Max. Tensile Strength = Short term Allowable tension ≈2×(Long term Allowable Tension) |

|

Short term:≤0.3% Long term:≤0.1% |

Short term: a <0.1 dB, a reversible; Long term: a ≤0.03 dB |

|||

| Crush | IEC 60794-1-2-E3 |

Short term: a <0.10 dB, a reversible; Long term: a ≤0.03 dB; The outer sheath has no visible crack. |

Short term crushing force =600 N Long term crushing force =300 N |

|

|

Repeated bending |

IEC 60794-1-2-E6 |

After test, a ≤0.03 dB; The outer sheath has no visible crack. |

R=20 outer Φ | |

| Bending load =15N | ||||

| Bending times =25 | ||||

| Torsion | IEC 60794-1-2-E7 |

After test, a ≤0.03 dB; The outer sheath has no visible crack. |

Torsion angle=±180º | |

| Torsion load =15N | ||||

| Torsion times =5 | ||||

| Cable bend | IEC 60794-1-2-E11A |

After test, The optical fiber can’t be broken; The outer sheath has no visible crack. |

R=20 outer Φ 10Turns Cycles times =5 |

|

| All optical testing proceeded at 1550 nm | ||||

Environment performance

| Item | Testing Method | Testing Results | ||

| Temperature cycling | IEC 60794-1-2-F1 | Allowable additional attenuation (1550nm) | ||

| G.652B | G.652D | G.657 | ||

| a ≤0.10 dB/km, a reversible; | ||||

| Water penetration | IEC 60794-1-2-F5B |

Water column: 1m, 3m cable, Period:24 hours No water leak through the open end of cable |

||

| Filling compound flow | IEC 60794-1-2-E14 |

70℃,Period:24 hours No compound flow from the cable |

||

Color Code of the Fiber

Each fiber can be identifiable throughout the length of the cable in accordance with the following color sequence. Fiber color in each tube starts from No. 1 Blue.

Fiber Colors

| No | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Blue | Orange | Green | Brown | Slate | White | Red | Black | Yellow | Purple | Pink | Aqua |

| No | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| Color | Blue | Orange | Green | Brown | Slate | White | Red | Natual | Yellow | Purple | Pink | Aqua |

<color> with evenly spaced black ring marks.

Color Code of the Loose Tube

The color of the tube will be natural.

Mechanical, Electrical and Environmental Test Characteristics

The finished cables can be subjected to the following mechanical, electrical and environmental conditions.

| Item | Test Method | Requirements |

| Tensile performance |

IEC 60794-1-21-E1 Load: 0.5G Cable length under tension: Not less than 50m. Duration of load sustain: 1min. Velocity of transfer device: 10mm/min |

The maximum increase in attenuation less than 0.1 dB . The maximum fiber strain less than 0.6% under maximum tensile short term load. No change in attenuation after test at 1550nm. Under visual examination without magnification, no damage to the sheath or to the cable elements after test. |

| Crush |

IEC 60794-1-21-E3 Load: 200N Duration of load: 1min |

No change in attenuation after test at 1550nm. Under visual examination without magnification, no damage to the sheath or to the cable elements. The imprint of the striking surface on the sheath is not considered mechanical damage. |

| Bend |

IEC 60794-1-21-E11A Mandrel radius: 10 times cable diameter Turns:4 Cycles:3 |

No change in attenuation at 1550nm after test. Under visual examination without magnification, no damage to the sheath or to the cable elements. |

| Repeated bending |

IEC 60794-1-21-E6 Bending radius: 20 times cable diameter Cycles: 25 Load: 25N Duration of cycle: Approximately 2s. |

No change in attenuation at 1550nm after test. Under visual examination without magnification, no damage to the sheath or to the cable elements. |

| Torsion |

IEC 60794-1-21-E7 Cycles:5 Length under test: 1m Turns: ±180° Load: 0.5G |

The variation on attenuation for each fiber less than 0.1dB at 1550nm Under visual examination without magnification, no damage to the sheath or to the cable elements. No permanent change in attenuation after test |

| Temperature cycling |

IEC 60794-1-22-F1 Sample length: at least 1000m Temperature range: -20℃~+70℃ Cycles: 2 Temperature cycling test dwell time: 12 hours |

No change in attenuation coefficient at 1550nm after test. |

|

Water Penetration |

IEC 60794-1-22-F5B Time : 24 hours Sample length : 3m Water height : 1m |

No water leakage |

| Compound flow |

IEC 60794-1-21-E14 Sample count:5 Sample length:300 ±5 mm, Remove length: 130 ±2,5 mm, Time:24h |

No filling compound dripped. |

| Jetting Performance | Conform to IEC 60794-5-10 | |

| Other parameters | Conform to IEC 60794 | |

Remark: “No attenuation changes” is considered as the attenuation changes ≤ 0.05 dB.

Standard delivery lengths are 2km, 4km, 6km with a tolerance of -1%~+3%

| Fiber Count | Drum length (m) | Drum Size Φ×W (mm) | Packing Size L×W×H (mm) | Weight (Gross) (kg) |

| 2~12 Fibers φ 2.0-2.5 | 2000 | Φ450×370 | 480×370×645 | 27 |

| 4000 | Φ500×370 | 530×370×695 | 39 | |

| 6000 | Φ550×370 | 580×370×745 | 51 | |

| 14~24 Fibers φ 2.8 | 2000 | Φ500×370 | 530×370×695 | 31 |

| 4000 | Φ550×370 | 580×370×745 | 46 |

◆ Packing

Wooden or plywood drums with protection.