Non Metallic GYFTY Fiber Optic Armoured Cable G652D 12 24 30 48 Core PE HDPE G657A2

Product Details:

| Place of Origin: | SHENZHEN |

| Brand Name: | KEXINT |

| Certification: | ISO-9001-2015 |

| Model Number: | GYFTY- 30 B1.3 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10KM |

|---|---|

| Price: | 0.59$/meter |

| Packaging Details: | 1.1*0.72*1.1m 2km~4km ,Length per roll , Wooden Drum |

| Delivery Time: | 7 |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 700+KM+7day |

|

Detail Information |

|||

| Application: | Outdoor Aerial Application | Fiber Type: | G652D/G657A1 |

|---|---|---|---|

| Length Per Roll: | 2km To 4km | Fiber Brand: | Corning/YOFC/FIBERHOME |

| Sheath Color: | Black | Fiber Count: | 30 Core |

| Package: | Wooden Drum | Type Of Optical Cable: | Power Optical Cable |

| Highlight: | armored fiber cable,armoured fiber cable |

||

Product Description

Non-metallic GYFTY Fiber Optic Armoured Cable G652D 12 24 30 48 Core PE HDPE G657A2

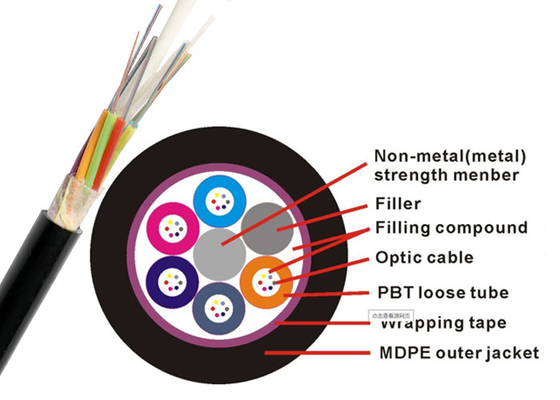

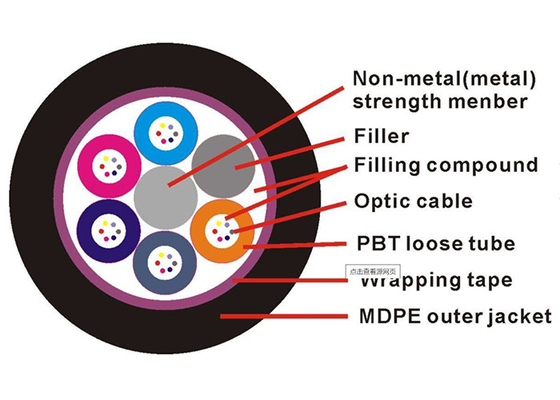

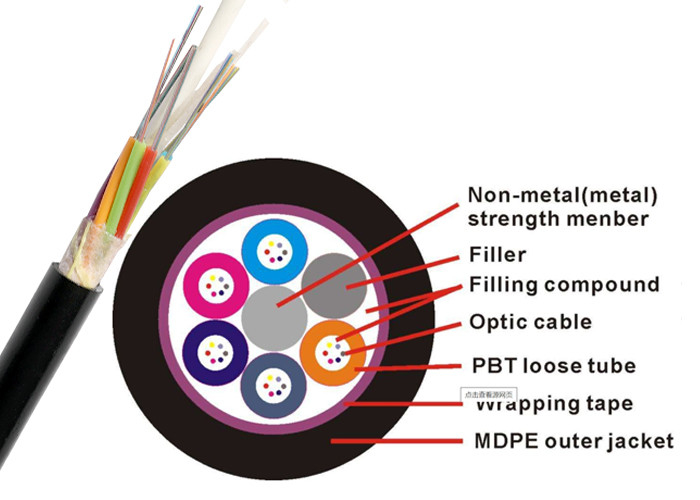

The center of GYFTY's optical cable is a glass fiber reinforced plastic (FRP). A loose tube (and a filling rope) is twisted around the center reinforcing core to form a compact and round cable core. The gap in the cable core is filled with a water blocking filler. The outer layer of the cable core is extruded with a polyethylene inner sheath to form a cable.

1 Cable design

- 48 SM-fibers

- G652 D operating wavelength at 1260~1625nm.

- FRP as central strength member.

- Loose buffer tubes SZ-stranded.

- The buffered tube filled with filling compound while the stranded core covered with water block material

- PE Cable inner sheath

- Aramid yarns as peripheral strength member

- PE Cable outer sheath(PE outer sheath is applied for the application in which cable is installed at the place where the spatial potential ≤12KV)

- Suitable as: Aerial installation (Span:400m)

2 Reference Standard

IEC 60793-1, 60793-2, 60794-1

ITU-T G650, G652

3 Optical and mechanical characteristics of fiber

| Fiber count | 2~30 | 32~36 | 38~60 | 62~72 | 74~84 | |||

| Loose Tube | OD(mm): | 1.8±0.1 | 1.8±0.1 | 2.0±0.1 | 2.0±0.1 | 2.0±0.1 | ||

| Material: | PBT | |||||||

| Max fiber count/tube | 6 | 6 | 12 | 12 | 12 | |||

| Core unit | 6 | 6 | 6 | 6 | 7 | |||

| FRP/Coating(mm) | 1.8 | 1.8 | 2.0 | 2.0 | 2.0/2.7 | |||

| Water Blocking Material | water-blocking Compound | |||||||

| Sheath | Thickness: | Non. 1.5mm | ||||||

| Material: | PE | |||||||

| OD of cable (mm) | 8.8±0.2 | 8.8±0.2 | 9.4±0.2 | 9.4±0.2 | 10.1±0.2 | |||

| Net weight ( kg/km) | 64 | 63 | 65 | 69 | 79 | |||

| Fiber count | 86~96 | 98~108 | 110~120 | 122~132 | 134~144 | |||

| Loose Tube | OD(mm): | 2.0±0.1 | 2.0±0.1 | 2.0±0.1 | 2.0±0.1 | 2.0±0.1 | ||

| Material: | PBT | |||||||

| Max fiber count/tube | 12 | 12 | 12 | 12 | 12 | |||

| Core unit | 8 | 9 | 10 | 11 | 12 | |||

| FRP/Coating(mm) | 2.5/3.4 | 2.5/3.4 | 3.0/4.7 | 3.0/5.3 | 3.0/6.0 | |||

| Water Blocking Material | water-blocking Compound | |||||||

| Sheath | Thickness: | Non. 1.5mm | ||||||

| Material: | PE | |||||||

| OD of cable (mm) | 10.8±0.2 | 11.4±0.2 | 12.1±0.2 | 12.7±0.2 | 13.4±0.2 | |||

| Net weight ( kg/km) | 92 | 102 | 116 | 127 | 141 | |||

4 Mechanical requirements and methods of fiber cable

| Tensile strength | 10935N, conform to IEC 794-1-E1,While Fiber Strain≤0.33% |

| Crush | 2200N/100mm, conform to IEC 794-1-E3 |

| Impact | conform to IEC 794-1-E4 |

| Repeated bending | conform to IEC 794-1-E6 |

| Torsion | conform to IEC 794-1-E7 |

| Flexing | conform to IEC 794-1-E8 |

| Kink | conform to IEC 794-1-E10 |

| Cable bend | conform to IEC 794-1-E11 |

| Vibration | conform to IEC 794-1 |

| Water penetration | conform to IEC 794-1-F5B |

| The dielectric strength of outer jacket | conform to ITU-T Rec.K25 |

| Spark test voltage | Spark test voltage of cable outer jacket will be no less than 8kV AC |

| Abrasion | conform to IEC 794-1-E2 |

| Temperature cycling test | conform to IEC 794-1-F1 |

5 Fiber color coding

6 Tube color coding

| Tube No | 1 | 2 | 3 | 4 | Filler |

| color | Blue | Orange | Green | Brown | Natural |

7 Mechanical specification

Single Mode Fiber

| LTEMS | UNITS | SPECIFICATION | ||

| Fiber type | G652D | G657A | ||

| Attenuation | dB/km |

1310nm ≤ 0.36 1550nm ≤ 0.22 |

||

| Chromatic Dispersion | ps/nm.km |

1310nm≤ 3.5 1550nm≤ 18 1625nm≤ 22 |

||

| Zero Dispersion Slope | ps/nm2.km | ≤ 0.092 | ||

| Zero Dispersion Wavelength | nm | 1300 ~ 1324 | ||

| Cut-off Wavelength (lcc) | nm | ≤ 1260 | ||

|

Attenuation vs. Bending (60mm x100turns) |

dB |

(30mm radius,100ring )≤ 0.1 @ 1625nm |

(10mm radius,1ring)≤ 1.5 @ 1625nm | |

| Mode Field Diameter | mm | 9.2 ± 0.4 at 1310nm | 9.2 ± 0.4 at 1310nm | |

| Core-Clad Concentricity | mm | ≤ 0.5 | ≤ 0.5 | |

| Cladding Diameter | mm | 125±1 | 125±1 | |

| Cladding Non-circularity | % | ≤ 0.8 | ≤ 0.8 | |

| Coating Diameter | mm | 245±5 | 245±5 | |

| Proof Test | Gpa | ≥ 0.69 | ≥ 0.69 | |

Multi Mode Fiber

| LTEMS | UNITS | SPECIFICATION | |||||||

| 62.5/125 | 50/125 | OM3-150 | OM3-300 | OM4-550 | |||||

| Fiber Core Diameter | μm | 62.5±2.5 | 50.0±2.5 | 50.0±2.5 | |||||

| Fiber Core Non-circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | |||||

| Cladding Diameter | μm | 125.0±1.0 | 125.0±1.0 | 125.0±1.0 | |||||

| Cladding Non-circularity | % | ≤2.0 | ≤2.0 | ≤2.0 | |||||

| Coating Diameter | μm | 245±10 | 245±10 | 245±10 | |||||

| C0at-Clad Concentricity | μm | ≤12.0 | ≤12.0 | ≤12.0 | |||||

| Coating Non-circularity | % | ≤8.0 | ≤8.0 | ≤8.0 | |||||

| Core-Clad Concentricity | μm | ≤1.5 | ≤1.5 | ≤1.5 | |||||

| Attenuation | 850nm | dB/km | 3.0 | 3.0 | 3.0 | ||||

| 1300nm | dB/km | 1.5 | 1.5 | 1.5 | |||||

| OFL | 850nm | MHz﹒km | ≥160 | ≥200 | ≥700 | ≥1500 | ≥3500 | ||

| 1300nm | MHz﹒km | ≥300 | ≥400 | ≥500 | ≥500 | ≥500 | |||

| The biggest theory numerical aperture | / | 0.275±0.015 | 0.200±0.015 | 0.200±0.015 | |||||

Mechanical and Environmental Performance of the Cable

| NO. | ITEMS | TEST METHOD | ACCEPTANCE CRITERIA |

| 1 |

Tensile Loading Test

|

#Test method:IEC 60794-1-E1 -. Long-tensile load:600N -. Short-tensile load:1.5 times the cable weight -. Cable length:≥50m |

-. Attenuation increment@1550nm:≤0.1dB -. No jacket cracking and fiber breakage |

| 2 | Crush Resistance Test |

#Test method:IEC 60794-1-E3 -.Long load:300 N/100mm -.Short load:1000 N/100mm Load time:1 minutes |

-. Attenuation increment@1550nm:≤0.1dB -. No jacket cracking and fiber breakage |

| 3 | Impact Resistance Test |

#Test method:IEC 60794-1-E4 -.Impact height:1m -.Impact weigh: 450g -.Impact point:≥5 -.Impact frequency:≥3/point |

-. Attenuation increment@1550nm:≤0.1dB -. No jacket cracking and fiber breakage |

| 4 | Repeated Bending |

#Test method:IEC 60794-1-E6 -.Mandrel diameter:20D (D = cable diameter) -.Subject weight:15kg -.Bending frequency:30 times -.Bending speed:2s/time |

-. Attenuation increment@1550nm:≤0.1dB -. No jacket cracking and fiber breakage |

| 5 | Torsion Test |

#Test method:IEC 60794-1-E7 -.Length:1m -.Subject weight:25kg -.Angle:±180 degree -.Frequency:≥10/point |

-. Attenuation increment@1550nm:≤0.1dB -. No jacket cracking and fiber breakage |

| 6 | Water Penetration Test |

#Test method:IEC 60794-1-F5B -.Height of pressure head:1m -.Length of specimen:3m -.Test time: 24 hours |

-. No leakage through the open cable end |

| 7 | Temperature Cycling Test |

#Test method:IEC 60794-1-F1 -.Temperature steps:+20℃,-40℃,+70℃,+20℃ -.Testing Time:24 hours/step -.Cycle index:2 |

-. Attenuation increment@1550nm:≤0.1dB -. No jacket cracking and fiber breakage |

| 8 |

Drop Performance

|

#Test method:IEC 60794-1-E14 -.Testing length:30cm -.Temperature range:70±2℃ -.Testing Time:24 hours |

-. No filling compound drop out |

| 9 | Temperature |

Operating:-40℃~+60℃ Store/Transport :-50℃~+70℃ Installation -20℃~+60℃ |

|

9 Environmentally

The product is accord with the instruction of EU ROHS

10 Packing and Logo

10.1 Packing

10.1.1 Each single length of cable shall be wound on an Iron stand-wooden composite drum.

10.1.2 Covered by plastic buffer sheet.

10.1.3 Sealed by strong wooden battens.

10.1.4 Drum length

10.1.4.1 Standard drum length is 4000m;

10.1.4.2 Total quantity is at least the ordered quantity.

10.1.4.3 Or it can be delivered according to customers’ requirements, but not longer than 5000m.

10.2. Drum Marking

- Manufacturer name;

- Manufacturing year and month;

- Roll-direction arrow;

- Cable outer end position indicating arrow;

- Cable type and size;

- Drum number;

- Drum length;

- Gross / net weight;

- Caution plate indicating the correct method for loading, unloading and convey the cable;

- Other customer information such as contract no., project no., and delivery destination. (if needed)

10.3 Cable identification documents

- Product qualified certificate;

Test report.

![]()

Package and Shipping:

1. All of our fiber optic cable package are with export wooden drum.

2. 2~3km/drum, Outdoor fiber optic cable's wooden dimension is 110cm*110cm*71cm, 0.85CBM,

3. Can be load about 39 drums for a 20GP.

Also accept custom cable drum from customers. welcome to contact us!

![]()

FAQ:

1. Are you the real factory

Yes,we are the real factory with 11 years’ history.

2. What is your fiber brand ?

Fiber brands including : NECERO,Corning,Fiberhome

3. What is your main products

Outdoor fiber optic cables; indoor fiber optic cables;FTTH Drop cables; ADSS;Fiber Optic Distribution Box

Indoor armored patch cords fiber cable; Optical patch cords SC/LC/FC/ST; MTP/MPO optical patch cord.

4. Product quality guarantee period?

25 years’ Guarantee for fiber optic cable

5. Do you have certificate for raw material ?

We build long-term relationship cooperation with qualified ISO9001, ROHS raw material suppliers.

6. What is your delivery time?

Within 24 hours for 30KM normal kinds of fiber optic cable;

1 ~2 days for fiber optic patch cords with 10000 connectors.

7.MOQ: what is your minimum quantity ?

MOQ for fiber optic cables: 1KM

There is no MOQ required for fiber optic patch cords,as there’s stock for normal kinds.

8.Do you have distributor in other country or domestic?

Until now, we sell our products to customers directly. And factory price could be offered.

9.Payment:

For large orders: T/T, L/C

For small orders: T/T,Western Union and Paypal are acceptable.

10.Shipping & Delivery:

For large orders: by sea (LCL or FCL)

For small orders: by sea (LCL), by air or by courier services,any of which is optional.