Outdoor Black Splice FOSC Fiber Optic Closure GPJ 96 Core Dome Overhead Safety

Product Details:

| Place of Origin: | SHENZHEN |

| Brand Name: | KEXINT |

| Certification: | ISO-9001 |

| Model Number: | KXT-W-048 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | $+10.67+1pcs |

| Packaging Details: | Carton Packaging |

| Delivery Time: | 8 |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 500+pcs+7day |

|

Detail Information |

|||

| Sealing Standard: | IP68 | Diameter Of Fiber Cable: | Φ12.5mm~Φ23 Mm |

|---|---|---|---|

| Size: | 420 × 150 × 110 Mm | Fiber Optical Quantity: | 12cores 24cores 48cores 96cores |

| Material: | PP | Application: | FTTH |

| Colour: | Black | Application Environment: | When Laid Overhead, In The Pipeline, Underground Or In The Well. |

| Highlight: | fiber optic joint box,optical fibre cable joint closure |

||

Product Description

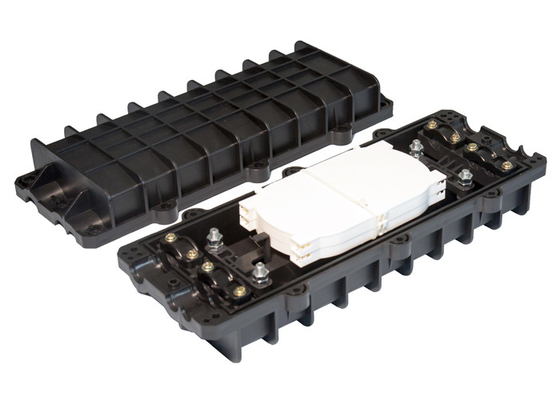

Black Splice FOSC Fiber Optic Closure GPJ 96 Core Dome Overhead Safety

Application:

KXT-W-048 is suitable for direct and divergent (one point two, one point three) connection of various types, structural fiber optic cables (single fiber and ribbon) within the diameter, φ23mm, overhead, pipeline, direct burying and laying into the well. At the same time, it is also suitable for connection of all plastic local telephone cables

Structural features:

1. All performance indicators of this product meet the requirements of national YD / T814-1996 standard.

2. The outer box is made of imported high-strength engineering plastics (ABS), high-pressure injection molding with the addition of anti-aging agents, and the shape is a rectangular shape with light weight, high mechanical strength, strong corrosion resistance, lightning resistance, long service life, etc. Features.

3. The outer box body and cable inlet are sealed with silicon rubber, which has reliable sealing performance, and is easy to be repeatedly opened and reused without loss.

4. The unique configuration of the plug allows users to make flexible choices based on the actual number of optical cables used.

5. The superimposed structure fused fiber tray and plastic main frame in the box make the insulation performance more reliable, the capacity expansion, and the optical cable grounding flexible, convenient and safe.

6. The metal components and fasteners on the outside of the box are made of stainless steel, which can meet the convenience and reuse in various environments.

Main technical Specifications:

-

1. Dimensions (mm): 420 × 150 × 110 2. Weight: 1.6kg 3. Optical fiber curvature radius: ≥40mm 4. Additional loss of optical fiber disk: ≤0.01dB 5. Retained optical fiber length: ≥1.6m 6. Maximum fiber capacity: single fiber: 96 cores 7. Applicable temperature range: -40~70 8. Anti-side pressure: ≥2000N / 10cm 9. Impact resistance: ≥20N.m

Operations:

1. Open and strip the optical cable, remove the outer sheath, inner sheath, and shrink tube, clean and remove the oil filling paste in the cable, and leave a fiber length of 1.1 to 1.6 m and a steel core of 30 to 50 mm.

2. Fix the compression cable card to fix the optical cable, and at the same time fix the optical cable to strengthen the steel core.

3. The optical fiber is introduced into the fusion splicing tray, and the heat shrinkable tube and the thermal fusion tube are sleeved on any one of the optical fibers to be spliced. After the optical fiber is spliced, the heat sink and the thermal fusion tube are moved, and a stainless steel (or quartz) reinforced core rod is placed. Position the optical fiber fusion splice at the center of the optical fiber protection tube, heat the protective tube appropriately, and fuse the optical fiber and the protective tube into one. The protected optical fiber connector is snapped into the fiber slot (each splicing disk can be equipped with 12 cores of optical fiber) ).

4. Distribute the remaining optical fibers evenly in the optical fiber fusion splicing disk, and arrange the coiled optical fibers with nylon cable ties. The splice tray is generally used from bottom to top. After all the optical fibers are connected, cover the cover on the top layer of the splice tray and fix it.

5. Locate and use the ground wire by yourself according to the engineering design requirements.

6. Wrap the optical cable with self-adhesive tape. At the same time, close the cable inlet of the unused connector box with a plug. Close the two pieces of the shell and squeeze the stainless steel bolts. It is required that the stress of the bolts should be symmetrical and uniform until they are fully tightened.

7. Position and fix the hangers for laying according to the laying requirements.

![]()

Packing list:

| Connector box body | 1 set Plugs: 6 |

| Self-adhesive tape | 1 roll Abrasive cloth: 1 |

| Welding mark | 1 piece Stainless steel screw (M5 × 35): 12 sets |

| Hexagon socket wrench | 1 pc. Hanger: 1 pc. |

| Optical fiber heat-shrinkable tube | 1 to 96; Cable tie: 1 to 40 |