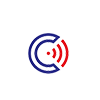

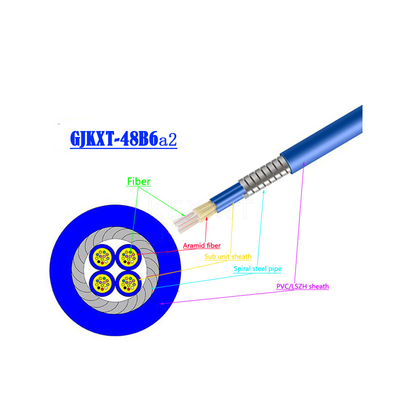

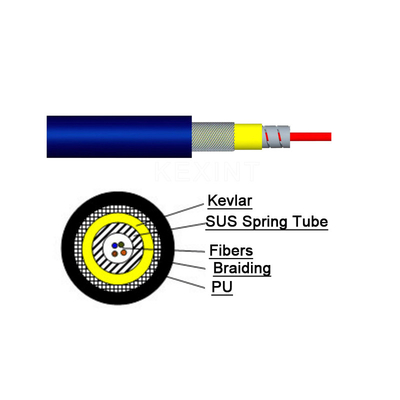

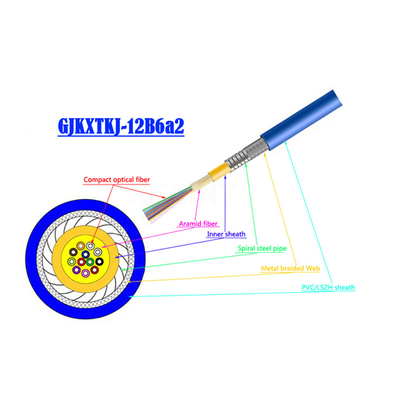

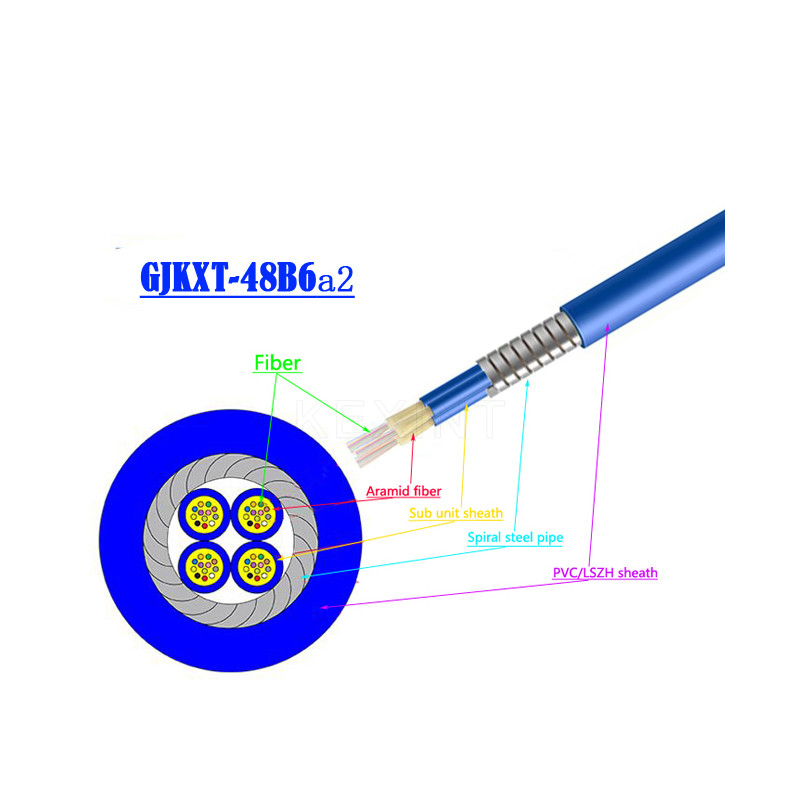

The structure of the optical cable is to twist together a ф900μm or ф600μm tight-buffered optical fiber and multiple strands of aramid fiber, extrude a layer of PVC or LSZH inner sheath on the stranded surface, and wrap a layer of flat stainless steel wirearmor outside the inner sheath. The surface is braided with stainless steel wire, and then extruded into a PVC or LSZH outer sheath.

Application:

·All kinds of connector

·Fiber optic pigtails, patch cords.

·Fiber optic equipment ,fiber optic patch panel,fiber to the desk,etc

·Fiber optic equipment and instrument

·Indoor cabling,building cabling,LAN, etc

·Long distance, outdoor/indoor cabling, trunking,etc

·Backbone network to the equipment in the building

·Small installation space cabling

Features:

·Multi fiber armored optical fiber cable has a layer of stainless steel wires enhance the crush resistance of the cable and anti-rodent

·High strength aramid yarn,high performance outer sheath

·Light weight,flexibility,and friendly installation.

·Good mechanical and environmental performance.

·Flame retardant outer sheath provide good safety.

1. The cable is wound on a non-returnable wooden drum. Both ends of cable are securely fastened to drum and sealed with a shrinkable cap. The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter. -Cable designation -Number of optical fiber -Manufacture name -Month/Year of Manufacture -Cable length The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

2. Drum marking Each side of every wooden drum shall be permanently marked in a minimum of 3 cm high lettering with following: -Manufacture name - Cable length - Number of fibers - Cable segment number - Inspection stamp and date

3. Packing and shipping The both end of each cable shall be sealed with suitable caps to prevent ingress of moisture. The factory length of the cable shall be wound on a strong wooden drum.