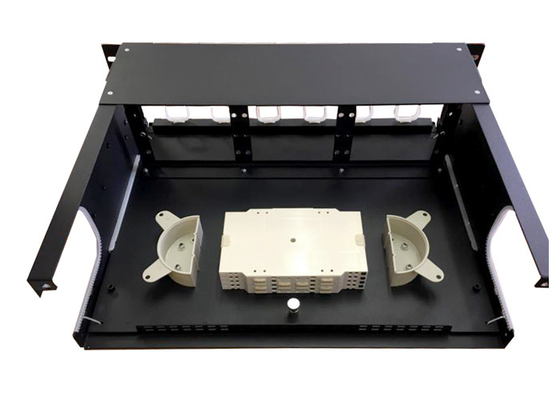

ODF 144FO Rack 12 Cassettes Optical Patch Panel

Product Details:

| Place of Origin: | SHENZHEN |

| Brand Name: | KEXINT |

| Certification: | ISO-9001 2015 |

| Model Number: | KXT-U-07 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 |

|---|---|

| Price: | $+104+PCS |

| Packaging Details: | Outer box:530*290*295/pcs ;Inner box:525*285*290/pcs |

| Delivery Time: | 7 |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 100+PCS+7Day |

|

Detail Information |

|||

| Connector Capacity: | 144 Pcs SC | Material: | Cold Rolled Steel Plate |

|---|---|---|---|

| Applications: | Rack Mountable Cabinet In Data Center | Type: | Hand Pull Type With 12 Cassettes |

| Dimensions: | 482mmx240mmx2U | Weight: | 12.5kg |

| Model Number:: | KXT-U-07--3u~4u | Color: | Black |

| Highlight: | ODF Optical Patch Panel,144FO Optical Patch Panel,ODF Patch Panel Rack Cabinet |

||

Product Description

ODF 144 FO Rack Fiber Optical Patch Panel Hand Pull Type 4U equipped with 12 cassettes

Optical fiber distribution frame (ODF) is used for the formation and distribution of the backbone optical cable at the local end in the optical fiber communication bai system, which can easily realize the connection, distribution and scheduling of optical fiber lines.

Application:

Structural features:

Main technical Specifications:

| 1 | Dimension(mm) | 482x253x4U |

| 2 | Weight | 12.5kg |

| 3 | optical fiber winding radius | ≥40mm |

| 4 | extra loss of fiber tray | none |

| 5 | fiber length left in tray | ≥1.6m |

| 6 | fiber capacity | 144 cores |

| 7 | working temperature | -400C ~ + 600C |

| 8 | lateral pressure-resistance | 500N |

| 9 | shock-resistance | 750N |

| 10 | Material | Cold-rolled steel sheet |

| 12 | Max capacity | 144 SC |

| 14 | Thickness | 1.2mm |

Operations:

1. Peel the cable , take off the outer and inner housing, as well as loose contract tube, and wash off the filling grease, leaving 1.1~1.6m fiber and 20~40mm steel core.

2. Fix the cable-pressing card and the cable, as well as the cable reinforce steel core.

3. Lead the fiber into the melting and connecting tray, fix heat contract tube and melted tube to one of the connecting fiber. After melting and connecting the fiber, move heat contract tube and melted tube and fix the stainless (or quartz) reinforce core stick ,make sure the connecting point is in the middle of the housing pipe. Heat the pipe to make the two into one.Put the protected joint into the fiber-laying tray.(one tray can lay 12 cores)

4. Lay the left fiber in the melting and connecting tray evenly, and fix the winding fiber with nylon ties. Use the trays from the bottom up. After all the fiber has been connected, cover the top layer and fix it.

5.Position it and use the earth wire in accordance with the project plan.

Packing List:

1. terminal case main body: 1 piece

2. polishing sand cloth: 1 pcs

3. melting and connecting mark: 1 pcs

4. heat shrinkable sleeve: 2~24 pcs

5. tie: 4~24 pcs

![]()

![]()

Our advantages:

1. Good reply: Your inquiry related to our products or price will be replied within 24 hours.

2. OEM&ODM: We can help you to design or put your logo and company name into products.

3. Remote Technical support&Full Technical Document

4. Warranty: 1 year warranty( While the warranty is not responsible for those broken by violence or updated with other brands.)

5. English software, English Indicator

6. Professional, Very competitive price

7. Large Stock, Fast Delivery